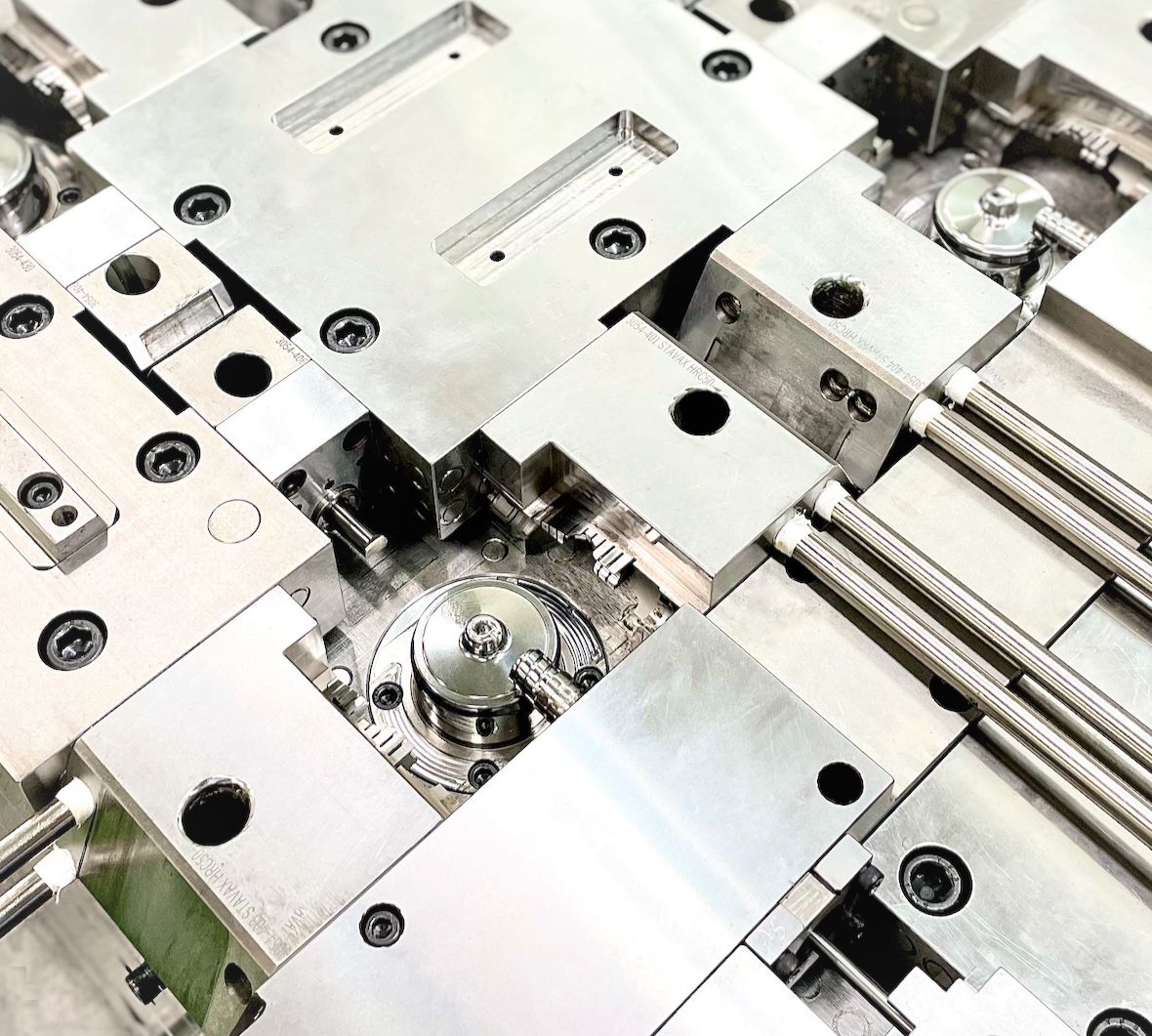

Mold / Tooling / Die Solutions

What is the key elements for precision mold design?

Precision mold design is essential for producing high-quality plastic components with tight tolerances and exacting specifications. Here are the key elements to consider in precision mold design:

-

Part Design Analysis: Conduct a detailed analysis of the part design to understand its critical features, tolerances, and functional requirements. Consider factors such as wall thickness, draft angles, surface finish, and geometric complexity that may affect mold design and part quality.

-

Material Selection: Choose the appropriate mold material based on the part requirements, production volume, and molding process conditions. High-quality tool steels, such as P20, H13, or stainless steel, are commonly used for precision mold applications due to their durability, wear resistance, and dimensional stability.

-

Tolerances and Dimensional Accuracy: Design the mold to achieve the desired part tolerances and dimensional accuracy. Consider factors such as shrinkage, material flow, and thermal expansion to compensate for dimensional variations during the molding process.

-

Gate Design: Select the appropriate gate type and location to ensure uniform filling of the mold cavity and minimize gate vestige on the finished part. Use small, precise gates positioned strategically to optimize material flow and minimize part distortion.

-

Runner and Cooling System: Design an efficient runner and cooling system to optimize material flow, reduce cycle times, and control part quality. Use proper runner sizing, layout, and cooling channel design to achieve uniform temperature distribution and minimize warpage.

-

Ejection System: Develop a robust ejection system to facilitate easy removal of the molded parts from the mold cavity. Design ejection pins, sleeves, or lifters for precise movement and alignment to ensure smooth ejection without damaging the parts.

-

Surface Finish and Texture: Specify the desired surface finish and texture for the molded parts based on aesthetic and functional requirements. Incorporate texturing or polishing into the mold design to achieve the desired surface appearance and feel.

-

Parting Line and Shutoff Surfaces: Define the parting line and shutoff surfaces in the mold design to separate the mold halves and form the part geometry accurately. Ensure proper alignment and fit between the mold halves to prevent flash or mismatch in the molded parts.

-

Venting: Incorporate venting channels or venting features into the mold design to allow for the escape of trapped air or gases during the molding process. Proper venting helps prevent air pockets, voids, and surface defects in the molded parts.

-

Tooling Maintenance and Accessibility: Design the mold for ease of maintenance and accessibility to facilitate cleaning, repair, and replacement of components. Provide access to critical areas, such as cavities, cores, and cooling channels, to ensure efficient mold maintenance.

-

Mold Inserts and Features: Integrate mold inserts, cores, slides, and lifters into the mold design to create complex part geometries and features. Design these components for precise movement and alignment to ensure accurate replication of part features.

-

Tooling Considerations: Consider tooling constraints, such as machine size, clamp force, and shot capacity, when designing the mold. Optimize the mold size, layout, and configuration to fit the injection molding machine and maximize production efficiency.

-

Simulation and Analysis: Utilize mold flow analysis and simulation tools to optimize the mold design and predict potential issues before manufacturing. Perform mold flow analysis to evaluate material flow, cooling efficiency, and part quality to refine the mold design and improve production outcomes.

By incorporating these key elements into precision mold design, engineers can develop molds that meet the stringent requirements of high-precision plastic component production, ensuring consistent quality, tight tolerances, and optimal performance.