Insert Molding / Overmolding

Insert Molding / Overmolding Application by Ming-Li Precison

Ming-Li Precision - A custom insert molder with expertise in custom insert molding and custom insert molded plastics.

MING-LI is a ISO/IATF 16949 approved insert molding company with core competence only severing consistent uncompromising quality insert molding product to our customer. We has many years of experience as a custom plastic insert molder.

Plastic injection insert molding is a plastic injection molding process in which thermoplastic material is molded around an insert piece or pieces placed in the plastic injection molding cavity, resulting in a single strongly bonded, integrated assembly, with the insert or inserts encapsulated by the plastic. Inserts can be metal, another plastic, ceramic or just about any substance that can withstand the plastic injection molding process.

Some of the first insert molding applications were for placing threaded inserts into molded parts and encapsulating wire plug connections on electrical cords.

- Reduced assembly and labor costsUmspritzen

- Reduced size and weight

- Improved component reliability

- Improved part strength and structure

- Enhanced design flexibility

- Consolidation of components

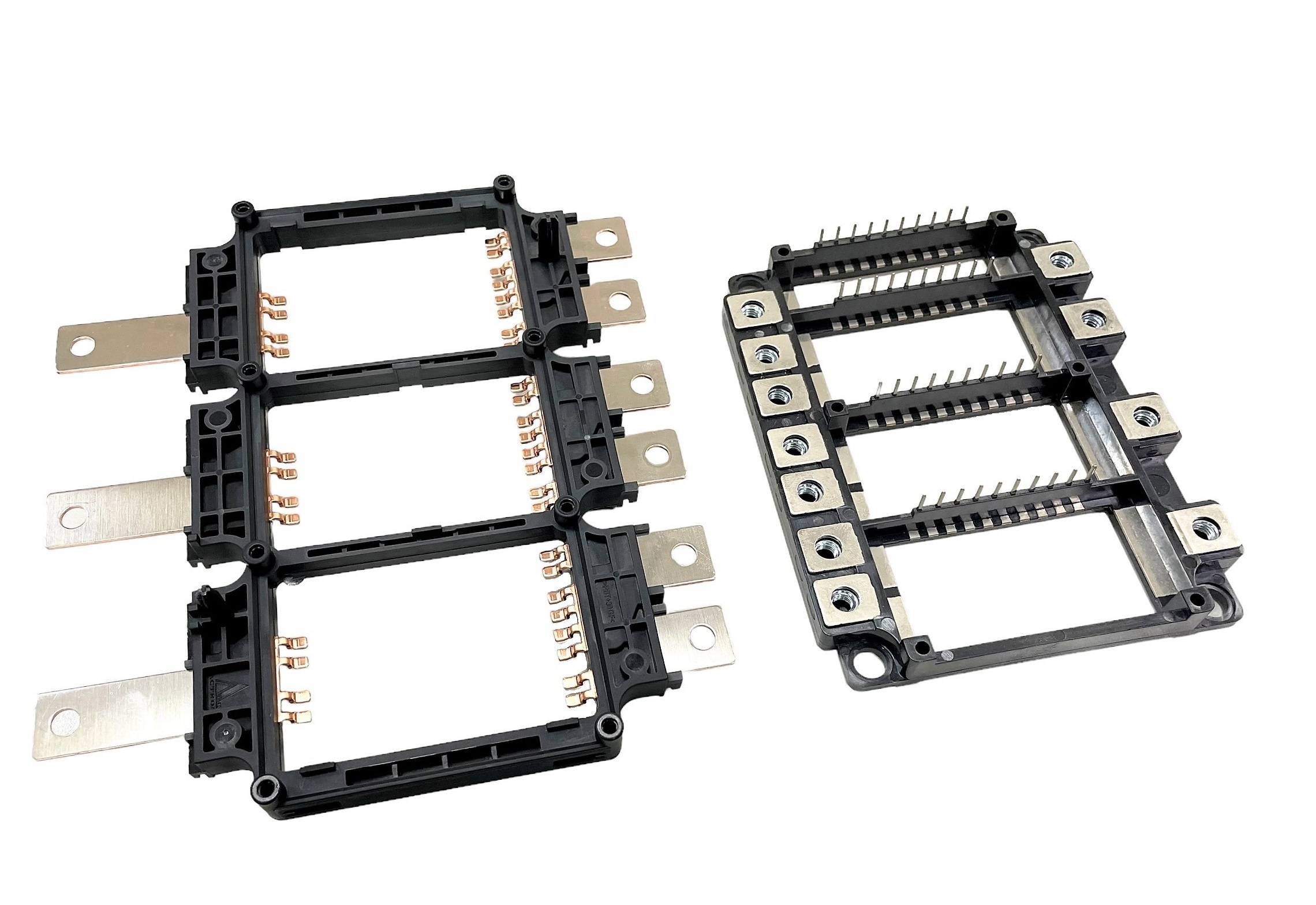

Our Insert Molding technology application for the IGBT inverter modules

The insert molding part technology is widely using on inverter, converter and power module for EV car applications recently. Ming-Li insert molding tehnology is an injection molding process in which a thermoplastic material is molded around an insert piece or pieces, creating a strongly bonded, integrated assembly. We combine knowledge about metal inserts, plating and molding expertise to create high technique parts. Selected our insert molding technique for the Insulated Gate Bipolar Transistor, IGBT-Inverter IGBT Modules. Insert molding technology finds several applications in the manufacturing of IGBT (Insulated Gate Bipolar Transistor) inverter modules, which are essential components in power electronics used for various applications, including motor drives, renewable energy systems, industrial automation, and electric vehicles. Here's how insert molding technology can be applied to IGBT inverter modules:

Circuit Board Encapsulation: Insert molding can be used to encapsulate the circuit boards and electronic components within the inverter module housing. This protects the delicate electronic components from environmental factors such as moisture, dust, and vibration, enhancing the reliability and longevity of the module.

Heat Sink Integration: Metal heat sinks can be integrated into the inverter module housing using insert molding. The heat sinks help dissipate heat generated during operation, improving the thermal management of the module and preventing overheating, which can degrade performance and reliability.

Wire Harness and Terminal Integration: Insert molding allows for the integration of wire harnesses, connectors, and terminals directly into the housing of the inverter module. This simplifies assembly, reduces the number of external connections, and minimizes the risk of wiring errors, improving overall reliability and reducing manufacturing costs.

Insulation and Electrical Isolation: Insert molding can provide insulation and electrical isolation between different components within the inverter module, such as power electronics, control circuitry, and input/output terminals. This helps prevent electrical shorts and ensures safe and reliable operation of the module in high-voltage applications.

Environmental Sealing and Protection: Insert molding creates a hermetic seal around the internal components of the inverter module, protecting them from moisture, dust, and other environmental contaminants. This is particularly important for outdoor or harsh environment applications where the module is exposed to extreme conditions.

Enhanced Mechanical Strength and Rigidity: By encapsulating components with a durable plastic material, insert molding improves the mechanical strength and rigidity of the inverter module housing. This helps withstand mechanical stresses, shocks, and vibrations encountered during operation or transportation, reducing the risk of damage or failure.

Customized Design Features: Insert molding allows for the integration of customized design features, such as mounting brackets, cooling channels, or cable management features, directly into the inverter module housing. This enhances the functionality, ease of installation, and serviceability of the module in different applications.

Overall, insert molding technology offers several benefits for the manufacturing of IGBT inverter modules, including improved reliability, thermal management, electrical performance, and mechanical robustness. By leveraging insert molding, manufacturers can produce high-quality inverter modules that meet the demanding requirements of modern power electronics applications.

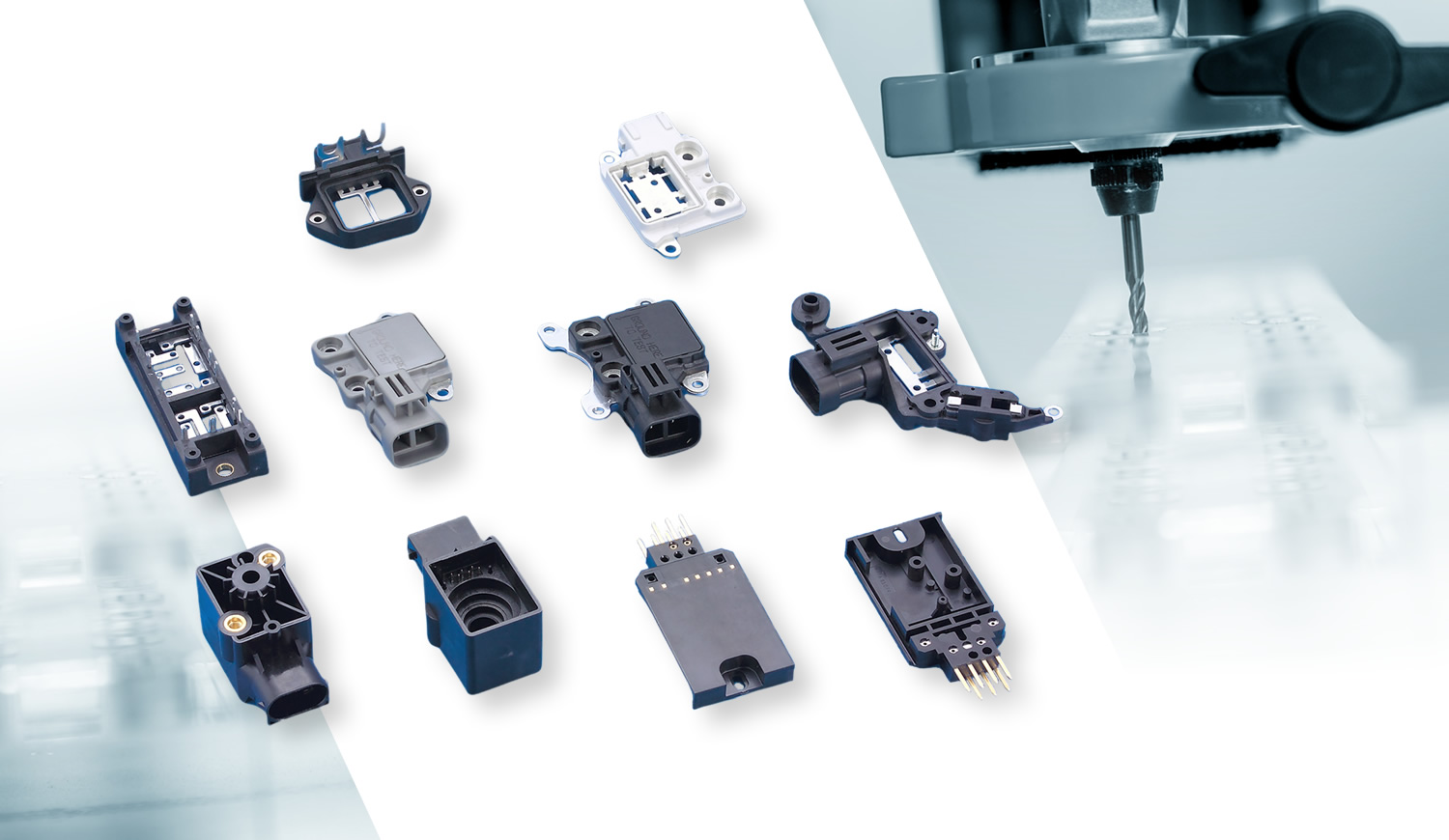

Our Insert Molding technology applicationfor the Alternator Regulator Brush Holder

Our insert molding tehnology is using a lot on the alternator regulator brrush holder parts. We have got full of experience on there insert molding brush holder parts. For this insert molding process, we combine knowledge about metal inserts, plating and molding expertise to create high technique parts. Selected our insert molding technique for the automotive parts, please contact us for more understanding. Insert molding technology is commonly applied in the manufacturing of alternator regulator brush holders, which are crucial components in automotive alternators responsible for regulating electrical output and transferring power from the rotor to the stator. Here's how insert molding technology can be used for alternator regulator brush holders:

Encapsulation of Components: Insert molding allows for the encapsulation of various components within the brush holder housing. This includes the regulator circuitry, brushes, terminals, and other electrical components necessary for regulating voltage output and transferring current.

Integration of Metal Inserts: Metal inserts, such as terminals or contact points, can be integrated into the brush holder housing using insert molding. These inserts provide secure electrical connections and mechanical stability, ensuring reliable performance under varying operating conditions.

Insulation and Electrical Isolation: Insert molding can provide insulation and electrical isolation between different components within the brush holder assembly. This prevents electrical shorts and ensures safe operation of the alternator by isolating conductive elements from each other.

Protection from Environmental Factors: The insert molding process creates a protective barrier around the internal components of the brush holder, shielding them from environmental factors such as moisture, dust, and vibration. This improves the reliability and longevity of the alternator in harsh operating conditions.

Enhanced Mechanical Strength: By encapsulating components with a durable plastic material, insert molding improves the mechanical strength and integrity of the brush holder assembly. This helps withstand mechanical stresses and vibrations encountered during operation, ensuring long-term reliability.

Customized Design Features: Insert molding allows for the integration of customized design features into the brush holder housing, such as mounting points, wire channels, or heat sinks. These features optimize the performance, installation, and serviceability of the alternator in different automotive applications.

Streamlined Manufacturing Process: Insert molding streamlines the manufacturing process by combining multiple assembly steps into a single operation. This reduces labor costs, assembly time, and the risk of assembly errors, leading to higher efficiency and consistency in production.

Overall, insert molding technology offers numerous advantages for the manufacturing of alternator regulator brush holders, including improved reliability, durability, and performance. By leveraging insert molding, manufacturers can produce high-quality brush holders that meet the stringent requirements of automotive alternator systems.

Our Insert Molding technology with multiple components

The insert molding is widely using in automotive industry. We have a multiple components insert molding project which is apply on automotive sensor parts. There are multiple components be insert durning the molding process. These components include metal pin, stampling insert, plastic, coil. etc. Insert molding technology is particularly advantageous when multiple components need to be integrated into a single part, offering benefits such as reduced assembly steps, improved part strength, and enhanced functionality. Here's how insert molding with multiple components works and some of its applications:

Component Integration: Insert molding allows for the integration of multiple components into a single part by placing them in the mold cavity before injecting molten plastic. These components can include metal inserts, electronic circuits, sensors, connectors, and other parts.

Enhanced Strength and Rigidity: By encapsulating multiple components within a plastic matrix, insert molding creates a strong and rigid part that can withstand mechanical stresses and environmental conditions. This improves the durability and longevity of the final product.

Reduced Assembly Time and Costs: Insert molding reduces the need for separate assembly steps by consolidating multiple components into a single part. This lowers labor costs, minimizes the risk of assembly errors, and streamlines the manufacturing process.

Complex Geometries and Features: Insert molding allows for the creation of complex part geometries and integrated features that would be difficult or impossible to achieve with traditional assembly methods. This enables designers to optimize part performance and functionality.

Improved Product Performance: By integrating multiple components, insert molding can enhance the performance and functionality of the final product. For example, sensors can be integrated into automotive components for monitoring temperature, pressure, or position, improving vehicle performance and safety.

Customized Design Solutions: Insert molding offers flexibility in design, allowing for the customization of parts to meet specific requirements. Different materials, colors, and textures can be used to achieve the desired appearance and performance characteristics.

Wide Range of Applications: Insert molding with multiple components is used across various industries and applications, including automotive, electronics, medical devices, consumer goods, and industrial equipment. It is particularly beneficial for producing parts with complex shapes, integrated electronics, and high-performance requirements.

Some specific examples of insert molding with multiple components include:

- Automotive Sensors: Integrated into components such as air intake manifolds, door handles, and steering wheel assemblies for monitoring various vehicle parameters.

- Medical Device Assemblies: Incorporating sensors, connectors, and electronic circuits into medical devices such as infusion pumps, patient monitors, and surgical instruments.

- Consumer Electronics: Integrating circuit boards, connectors, and buttons into electronic devices such as remote controls, game controllers, and wearable gadgets.

- Industrial Equipment: Incorporating sensors, connectors, and wiring harnesses into components for machinery, automation systems, and control panels.

Overall, insert molding with multiple components offers manufacturers a versatile and efficient solution for producing complex parts with integrated features and improved performance across a wide range of industries and applications.

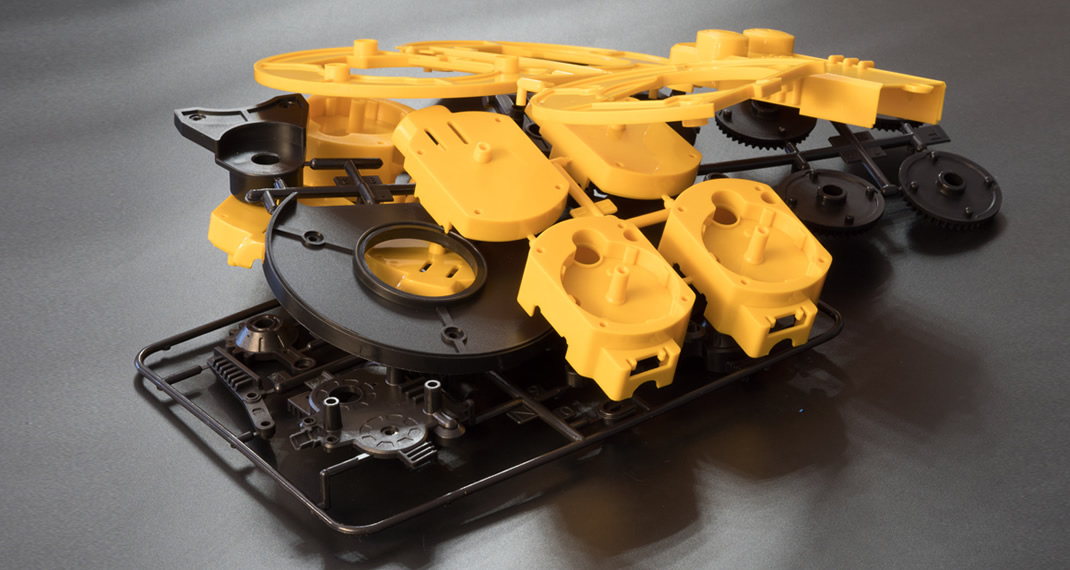

Our Insert Molding technology with Fine Blanking

The insert molding is widely using in many industry. We have a new bike part project recently. This part use insert molding with fine blanking stamping part. The plastic material is PPS-GF40, the fine blankiing stamping part material is SUS303.Insert molding technology can be combined with fine blanking to create complex parts with high precision and tight tolerances. Fine blanking is a specialized metal stamping process that produces parts with exceptionally smooth edges and accurately formed features. When used in conjunction with insert molding, it offers several advantages:

Precision Integration: Fine blanked metal components can be precisely integrated into the mold cavity before the injection of molten plastic. This ensures accurate positioning of the insert and tight dimensional control in the final part.

High-Quality Surface Finish: Fine blanking produces parts with smooth edges and minimal burrs, which are ideal for insert molding applications. The smooth surface finish of the metal insert promotes strong adhesion with the overmolded plastic, resulting in a seamless interface between the two materials.

Complex Geometries: Fine blanking enables the production of complex metal components with intricate shapes, holes, and features. These components can be seamlessly integrated into the mold design, allowing for the creation of parts with complex geometries and integrated functionalities.

Tight Tolerances: Fine blanking offers tight tolerances and dimensional accuracy, ensuring that the metal inserts meet precise specifications. This is essential for achieving proper fit, alignment, and functionality in the final insert molded part.

Enhanced Strength and Durability: Fine blanked metal inserts typically exhibit high strength and durability due to their uniform material properties and precise forming process. When integrated into an insert molded part, they provide structural reinforcement and enhance overall part performance.

Cost Efficiency: While fine blanking and insert molding are both precision manufacturing processes, combining them can offer cost savings by reducing the number of assembly steps and optimizing material usage. This can result in lower production costs and improved overall efficiency.

Applications of insert molding with fine blanking include:

Automotive Components: Fine blanked metal inserts can be integrated into automotive parts such as sensor housings, connectors, brackets, and handles. These parts require high precision, durability, and dimensional stability, making them well-suited for insert molding with fine blanking.

Electrical and Electronic Devices: Fine blanked metal inserts can be used in the production of electrical and electronic components such as connectors, terminals, and housing assemblies. These components require precise positioning, tight tolerances, and reliable electrical performance, which can be achieved through insert molding with fine blanking.

Medical Devices: Fine blanked metal inserts can be incorporated into medical device components such as surgical instruments, implantable devices, and diagnostic equipment. These parts require biocompatibility, corrosion resistance, and dimensional accuracy, making insert molding with fine blanking an ideal manufacturing solution.

Overall, combining insert molding with fine blanking allows manufacturers to produce high-quality, complex parts with tight tolerances and integrated functionalities for a wide range of applications across industries.

Our Insert Molding technology application for the EV car charging coonnectors

Insert molding technology is particularly well-suited for the production of electric car charger connectors due to its ability to integrate metal components directly into plastic parts. Here's how insert molding can be applied in this context:

-

Integration of Metal Contacts: Electric car charger connectors typically require metal contacts or pins to establish electrical connections. Insert molding allows these metal components to be securely embedded within the plastic housing during the molding process. This integration ensures reliable electrical conductivity while eliminating the need for additional assembly steps.

-

Enhanced Durability: By encapsulating metal contacts within the plastic housing, insert molding provides protection against environmental factors such as moisture, dust, and vibration. This helps to prolong the lifespan of the connectors and ensures consistent performance over time, even in demanding automotive applications.

-

Streamlined Production: Insert molding enables the simultaneous molding of plastic and metal components, resulting in a more streamlined production process. This reduces manufacturing lead times and overall production costs compared to traditional assembly methods, where metal contacts would need to be separately attached to plastic housings.

-

Design Flexibility: Insert molding offers designers greater flexibility in creating complex connector designs. By allowing metal inserts to be precisely positioned within the mold cavity, manufacturers can optimize the layout of electrical contacts to meet specific performance requirements and compatibility standards for electric car charging systems.

-

Improved Aesthetics: Integrating metal components within the plastic housing through insert molding can enhance the aesthetics of electric car charger connectors. This allows for sleek and compact designs that contribute to the overall visual appeal of electric vehicles while maintaining functionality and reliability.

-

Material Compatibility: Insert molding supports the use of a wide range of plastic resins suitable for automotive applications, including high-temperature and impact-resistant materials. Manufacturers can select materials that meet the performance, durability, and regulatory requirements of electric car charger connectors while ensuring compatibility with the insert molding process.

Overall, insert molding technology offers numerous advantages for the production of electric car charger connectors, including improved durability, streamlined production, design flexibility, and enhanced aesthetics. By leveraging insert molding, manufacturers can produce high-quality connectors that meet the demanding standards of electric vehicle charging systems.

Our Insert Molding technology application for the coonnectors housing

Insert molding is a manufacturing process used to create connector housings by integrating metal inserts, such as terminals or other components, into a plastic housing during the molding process. This technique enhances the structural integrity and functionality of the final product. Here's an overview of how insert molding is applied to connector housings:

- Electrical Connectors: Insert molding is used to embed metal terminals and pins within a plastic housing, creating a robust and reliable connector. This is common in automotive, consumer electronics, and telecommunications industries.

- High-Durability Components: Insert molding produces connector housings that need to withstand mechanical stress, vibration, and environmental factors, enhancing their durability and performance.

Insert Molding Process for Connector Housings

-

Mold Design and Fabrication:

- Design: The mold is designed to hold the metal inserts in place during the injection process. This includes creating cavities and features that secure the inserts.

- Fabrication: Precision tooling is used to manufacture the mold, ensuring high accuracy and repeatability.

-

Placement of Inserts:

- Manual or Automated Placement: Metal inserts (e.g., terminals, pins) are placed into the mold either manually or using automated systems.

- Securing Inserts: Inserts are secured in the mold to prevent movement during the injection of molten plastic.

-

Injection Molding:

- Material Injection: Molten plastic is injected into the mold under high pressure, filling the cavities and encapsulating the inserts.

- Cooling: The mold is cooled, allowing the plastic to solidify around the inserts, forming a strong bond.

-

Part Ejection and Post-Processing:

- Ejection: Once the plastic has cooled and solidified, the mold is opened, and the finished connector housing is ejected.

- Trimming and Inspection: Any excess plastic (flash) is trimmed off, and the parts are inspected for quality and functionality.

Advantages of Insert Molding for Connector Housings

- • Enhanced Strength and Durability: The integration of metal inserts within the plastic provides increased mechanical strength and durability.

- • Improved Electrical Performance: Ensures reliable electrical connections by securely embedding metal terminals and pins.

- • Design Flexibility: Allows for complex shapes and configurations, accommodating various design requirements.

- • Cost Efficiency: Reduces the need for additional assembly steps, saving time and manufacturing costs in high-volume production.

Examples

- • Automotive Connectors: Insert molding is used to produce connectors that must endure harsh environmental conditions, such as heat, moisture, and vibration.

- • Consumer Electronics: Ensures reliable connections in devices like smartphones, laptops, and other portable electronics.

Our Insert Molding technology application for the Induction Coil

Insert molding technology is highly suitable for the production of induction coils, particularly due to its ability to combine metal and plastic components into a single, cohesive unit. Here's how this technology is applied:

Application of Insert Molding in Induction Coils

-

Integration of Metal Components: In the case of induction coils, the metal wire, which is essential for the coil’s function, is placed into the mold. This wire can be made of copper or other conductive materials. The insert molding process allows this wire to be precisely positioned within the mold, ensuring that the final product meets the required specifications for electrical performance.

-

Encapsulation: Once the metal wire is placed in the mold, the plastic or polymer material is injected around it. This encapsulation process protects the wire from environmental factors such as moisture, dust, and mechanical damage. It also provides electrical insulation, which is critical for the safety and efficiency of the induction coil.

-

Design Flexibility: Insert molding allows for complex shapes and designs, which can be essential for creating custom induction coils that fit specific applications. The process also ensures that the metal insert is securely anchored within the plastic, reducing the risk of movement or misalignment.

-

Improved Durability and Performance: The encapsulation of the coil wire within a plastic housing through insert molding enhances the durability of the induction coil. It prevents wear and tear of the wire, thereby extending the lifespan of the coil. Additionally, the molded plastic can be designed to improve the heat dissipation properties, which is crucial in applications where the coil is subject to continuous operation.

-

Applications: Induction coils produced using insert molding technology are commonly used in various applications, including inductive charging devices, transformers, inductors, and electromagnetic interference (EMI) shielding components.

By leveraging insert molding technology, manufacturers can achieve high precision, repeatability, and efficiency in producing induction coils, ensuring optimal performance in their respective applications.

Our Insert Molding technology application for the Silicon Steel Sheet

Silicon steel sheet insert molding plays a critical role in the production of high-performance components for various electrical and electromagnetic applications. This advanced molding technique ensures that silicon steel sheets, known for their excellent magnetic properties, are precisely integrated into molded parts, enhancing the efficiency and reliability of the final products. Key applications include:

-

Transformers: Silicon steel sheets are integral in transformer cores, where their high magnetic permeability and low energy loss are essential for improving energy efficiency. The insert molding process securely embeds these sheets into the core, ensuring consistent performance and durability over time.

-

Electric Motors: In electric motors, silicon steel sheet insert molding is used to create stators and rotors with enhanced magnetic properties. This leads to motors that are more efficient, with reduced energy consumption and improved operational stability, making them ideal for high-demand applications.

-

Inductors: The precise placement of silicon steel sheets within molded inductor components ensures optimal magnetic flux and minimal energy loss. This is particularly important in electronic circuits where performance and reliability are critical.

-

Magnetic Coils: Silicon steel sheet insert molding is also used in the production of magnetic coils, where the material’s properties contribute to higher efficiency and better overall performance in electromagnetic devices, such as sensors and actuators.

This technology is vital for industries that rely on high-performance magnetic components, offering a combination of precision, efficiency, and reliability that meets the stringent demands of modern electrical applications.

Others Our Insert Molding technology application

Proper mold design and construction are critically important in insert molding to maintain part tolerances and tooling reliability. Ming-Li Plastics often employs automation in the insert molding process for fast and precise placement of inserts.

From concept to delivery, learn more about the competitive advantage Ming-Li Plastics provides OEMs with custom plastic injection molding and insert molding, through early supplier involvement in the design and engineering phase, design for manufacturability, project management, in house mold building, material selection support and via our global locations.

Contact Ming-Li Plastics today to start a conversation about your custom insert molded plastic needs, or to review your current components and assemblies to see if custom insert molding can give you a competitive advantage!

Insert molding finds applications in various industrier due to its ability to combin different materials and componets into a single integrated part. Some common applications of insert molding include:

Automotive Components: Insert molding is extensively used in the automotive industry for manufacturing parts such as connectors, switches, sensors, knobs, handles, and interior trim components. Metal inserts can be overmolded with plastic to provide added strength, durability, and functionality to these parts.

Electronics and Electrical Components: Insert molding is employed in the production of electronic connectors, sockets, housings, and other components where precise alignment, electrical conductivity, and protection against moisture and environmental factors are required. Metal contacts and wires can be encapsulated with plastic to create sealed and robust electrical assemblies.

Medical Devices: Insert molding is utilized in the medical device industry for manufacturing components such as catheters, surgical instruments, syringe components, and drug delivery devices. It enables the integration of metal or polymer inserts with biocompatible materials to create complex and functional medical products with enhanced performance and reliability.

Consumer Goods: Insert molding is commonly used in the production of consumer goods such as tools, appliances, sporting equipment, and household items. It allows for the incorporation of metal inserts into plastic parts to enhance strength, grip, and ergonomics, as well as to create aesthetically pleasing designs.

Industrial Equipment: Insert molding is applied in the manufacturing of industrial equipment and machinery components, including gears, handles, knobs, and enclosures. It enables the creation of durable and high-performance parts that can withstand harsh operating conditions, temperature variations, and mechanical stresses.

Telecommunications: Insert molding is employed in telecommunications equipment for producing components such as connectors, housings, antennas, and handheld devices. It enables the integration of metal inserts with plastic materials to achieve superior mechanical properties, electromagnetic shielding, and signal transmission capabilities.

Aerospace and Defense: Insert molding is utilized in the aerospace and defense industries for manufacturing components such as switches, connectors, housings, and avionics equipment. It allows for the creation of lightweight, durable, and high-performance parts that meet stringent requirements for reliability, safety, and functionality.

Overall, insert molding offers a versatile and cost-effective solution for producing complex parts with integrated features, improved performance, and enhanced durability across a wide range of industries and applications.

Ming-Li Insert Molding Project Example