DMLS – Direct Metal Laser Sintering

DMLS : Additive Metal Manufacturing

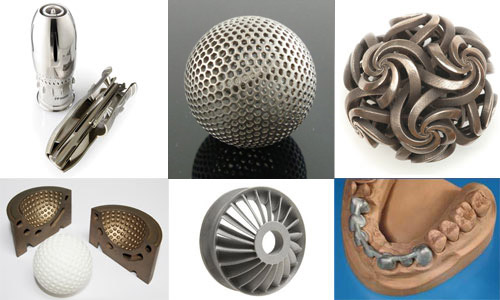

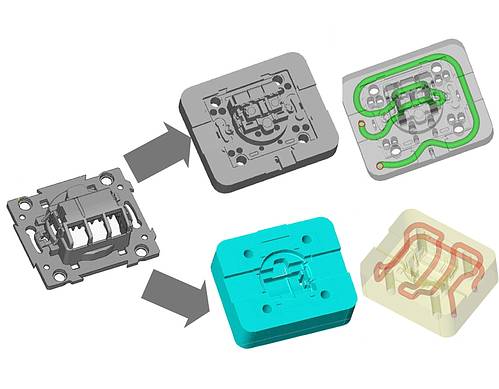

DMLS is the acronym for “direct metal laser sintering”. DMLS allows for highly complex geometries to be created directly from the 3D model. The process uses a high-power laser and scanner system to fuse fine metal powder, layer by layer, to create fully dense parts. Since 2013, Ming Li has been known for our extensive capabilities utilizing direct metal laser sintering (DMLS) to produce complex geometries. This process It is fully automatic, allows parts to be finished in hours and without any tooling.

DMLS : Additive Metal Manufacturing

High Speed: because no special tooling is required, from 2D or 3D model, complex parts can be built in days not months.

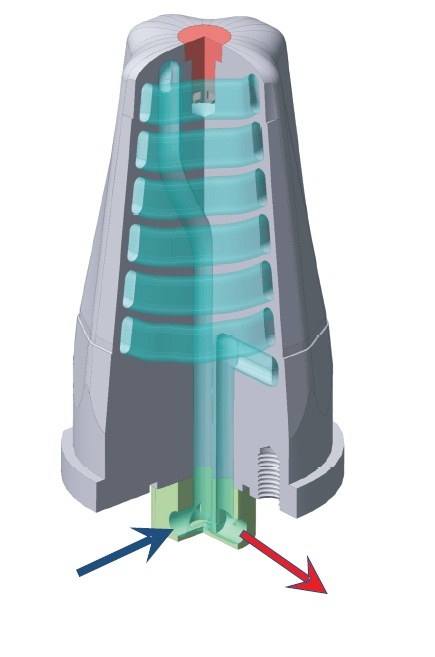

Complex Geometries: highly complex & internal geometry components, conformal cooling passages, and lattice structures parts can be accurately created quickly.

Cost Savings: fully functional parts produced without tooling and company can carry fewer inventories.

Material Properties: most metal alloys can be used, prototypes can be made out of the same material as production components.

Standard materials include:

- EOS Aluminium AlSi10Mg

- EOS CobaltChrome MP1

- EOS CobaltChrome SP2

- EOS MaragingSteel MS1

- EOS NickelAlloy IN625

- EOS NickelAlloy IN718

- EOS StainlessSteel GP1

- EOS StainlessSteel PH1

- EOS Titanium Ti64

DMLS parts product application

DMLS : Additive Metal Manufacturing