Q.C. Measuring Instrument List

| Machine Name | Brand | Part No | Origin | Machine Precision |

|---|---|---|---|---|

| 3D X-Ray CT scan | ZEISS |

METROTOM 6 |

Germany | Accuracy: ±2 µm |

| 3D scan measuring | ZEISS |

ATOS Capsule |

Germany | Accuracy: ± 0.002mm |

| 3 MM | ZEISS |

O-INSPECT 322 |

Germany | Accuracy: ± 0.002mm |

| 3 MM Projector | MICRO VU. | VERTEX320 | USA | Accuracy: ± 0.002mm |

| 3 MM Projector | HEXAGON | Optiv Performance | Germany | Accuracy: ± 0.002mm |

| 3 MM | TOKYO SEIMTUS | CVA600A | Japan | Accuracy: ± 0.002mm |

| 3 MM Projector | Chien Wei | CE-503 | Taiwan | Accuracy: ± 0.003mm |

| 2 D Projector | CHIEN WEI (CW) | CW-2515 | Taiwan | Accuracy: ± 0.003mm |

| Roundness Machine | TOKYO SEIMTUS | E-MD-134A | Japan | Accuracy: ± 0.001mm |

| Precision Microscope | VPRO MICROSOPE | 0.65~45X | Japan | Accuracy: ± 0.0005mm |

| Optics Projector | NIKON | V12 | Japan | Accuracy: ± 0.002mm |

| Tool Microscope | ZEISS |

ZKM01-250C |

Germany | Accuracy: ± 0.0001mm |

| Tooth Measurement | HOMMEL WERKE | ZWG8305 | Germany | Accuracy: ± 0.001mm |

| 3D magnifying | MANTIS | Visin | Japan | Accuracy: ± 0.002mm |

| Altimeter | Mitutoyo | IDF-150E | Japan | Accuracy: ± 0.002mm |

| Moisture balance | Precisaxm60 | Max 62 g d=0.001g | Japan | Accuracy: ± 0.001g |

| Gauge | DELTRONIC | ψ0.50m/m~14.00m/m | USA | Accuracy: ± 0.002mm |

| Digital Altimeter | TRIMOS | TVA600 | Switzerland | Accuracy: ± 0.001mm |

| Digital Altimeter | TESA | M600 | Switzerland | Accuracy: ± 0.001mm |

| Electronic Balnace | GROUP PROSPERS | MatsuHaku MH-200E | Taiwan | Accuracy: ± 0.001g |

| Engraves Machine | SOOMA | MP100 | Taiwan | Accuracy: ± 0.005mm |

| CNC Double Flank Gear Rolling Tester | Tokyo Technical Instruments | Tf-40nc | Japan | Accuracy: ± 0.002mm |

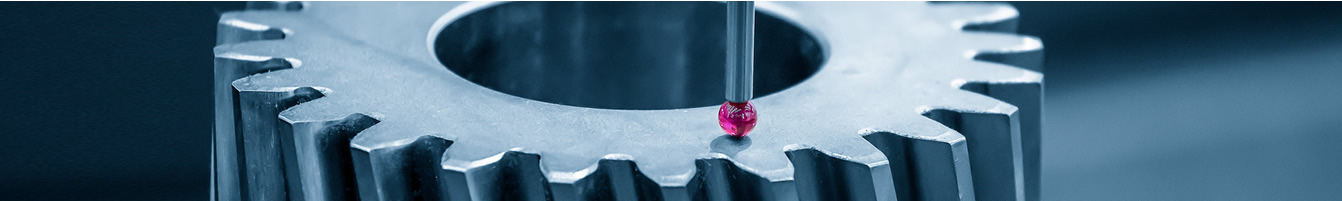

Key elements for precision plastic injection mold measuring

Achieving precision in plastic injection mold measuring involves several key elements to ensure accurate and consistent results. Here are some essential factors to consider:

-

Measurement Equipment: Invest in high-quality measurement equipment such as coordinate measuring machines (CMMs), optical comparators, height gauges, and digital calipers. The accuracy and precision of the measurement tools directly impact the quality of mold measurements.

-

Calibration: Regularly calibrate all measurement equipment to ensure accuracy. Calibration should be performed according to established standards and guidelines. Keep records of calibration dates and results for traceability.

-

Standard Operating Procedures (SOPs): Develop comprehensive SOPs for mold measurement procedures. SOPs should include detailed instructions for measurement techniques, equipment setup, data recording, and quality control checks.

-

Training and Skill Development: Provide training to personnel responsible for mold measurements. Ensure they are proficient in using measurement equipment and following SOPs accurately. Continuous skill development and training programs help maintain consistency in measurement practices.

-

Reference Standards: Use certified reference standards, such as gauge blocks and calibration artifacts, to verify the accuracy of measurement equipment and calibrate measurement tools. Reference standards should be traceable to national or international standards.

-

Temperature and Environmental Control: Maintain a stable temperature and environmental conditions in the measurement area to minimize thermal expansion and contraction effects on measurement accuracy. Use climate-controlled rooms or enclosures if necessary.

-

Measurement Techniques: Employ appropriate measurement techniques based on the geometry and features of the mold components. Ensure consistent measurement methodology across different parts of the mold to maintain accuracy and repeatability.

-

Data Management and Analysis: Implement robust data management systems to store, analyze, and track measurement data effectively. Use software tools for statistical analysis and process control to identify trends, deviations, and areas for improvement.

-

Quality Assurance Checks: Conduct regular quality assurance checks on measurement processes and equipment to verify accuracy and reliability. Perform gauge repeatability and reproducibility (GR&R) studies to assess measurement system capability.

-

Documentation and Traceability: Document all measurement results, including part dimensions, tolerances, and inspection records. Establish traceability by linking measurement data to specific molds, production runs, and quality control measures.

By focusing on these key elements, manufacturers can ensure precision in plastic injection mold measuring, leading to improved product quality, reduced waste, and enhanced overall manufacturing efficiency.

Key elements for precision plastic injection parts measuring

Achieving precision in measuring plastic injection parts is crucial for ensuring the quality and functionality of the final products. Here are key elements to consider for precision measurement:

-

Measurement Equipment Selection: Choose appropriate measurement tools based on the specific features and dimensions of the plastic parts. Common equipment includes coordinate measuring machines (CMMs), optical measurement systems, digital calipers, micrometers, and height gauges.

-

Accuracy and Calibration: Ensure that all measurement equipment is properly calibrated and regularly maintained. Calibration should adhere to relevant standards and guidelines. Regular verification checks should be conducted to ensure the accuracy and reliability of the measurement equipment.

-

Standardized Measurement Procedures: Develop standardized measurement procedures to ensure consistency and repeatability across different parts and operators. Document these procedures in detail, including measurement techniques, equipment settings, and data recording methods.

-

Training and Skill Development: Provide comprehensive training to operators responsible for measuring plastic parts. Training should cover proper equipment usage, measurement techniques, interpretation of measurement data, and adherence to standardized procedures.

-

Measurement Environment Control: Maintain a controlled measurement environment to minimize environmental factors that could affect measurement accuracy, such as temperature variations, humidity, and vibrations. Use climate-controlled rooms or enclosures when necessary.

-

Sampling and Statistical Analysis: Develop sampling plans for measuring plastic parts during production. Implement statistical analysis techniques, such as statistical process control (SPC), to monitor and analyze measurement data for trends, variations, and potential issues.

-

Measurement Repeatability and Reproducibility (Gage R&R): Perform measurement system analysis, such as Gage R&R studies, to assess the repeatability and reproducibility of the measurement process. Identify and address sources of variation to improve measurement consistency.

-

Feature-Specific Measurement Techniques: Tailor measurement techniques to specific features and dimensions of the plastic parts. For example, use appropriate measurement tools and methods for measuring surface finish, dimensional accuracy, wall thickness, and critical tolerances.

-

Documentation and Traceability: Document all measurement results, including part dimensions, tolerances, and inspection records. Establish traceability by linking measurement data to specific production batches, molds, or individual parts.

-

Continuous Improvement and Feedback Loop: Implement a continuous improvement process to address measurement challenges, optimize measurement techniques, and enhance overall measurement accuracy. Encourage feedback from operators and quality control personnel to identify areas for improvement.

By focusing on these key elements, manufacturers can ensure precision in measuring plastic injection parts, leading to improved product quality, reduced scrap rates, and enhanced customer satisfaction.